Cutting edge technology with highly professional and technical staff

ReFab prides itself on its highly professional technical staff. Our laser operators have experience operating many types of machines, materials and thicknesses. We have kept current with laser cutting technology, and are well versed in this technology from its infancy to the well-recognized manufacturing process that it is today.

Laser Cutting Technology as ReFab

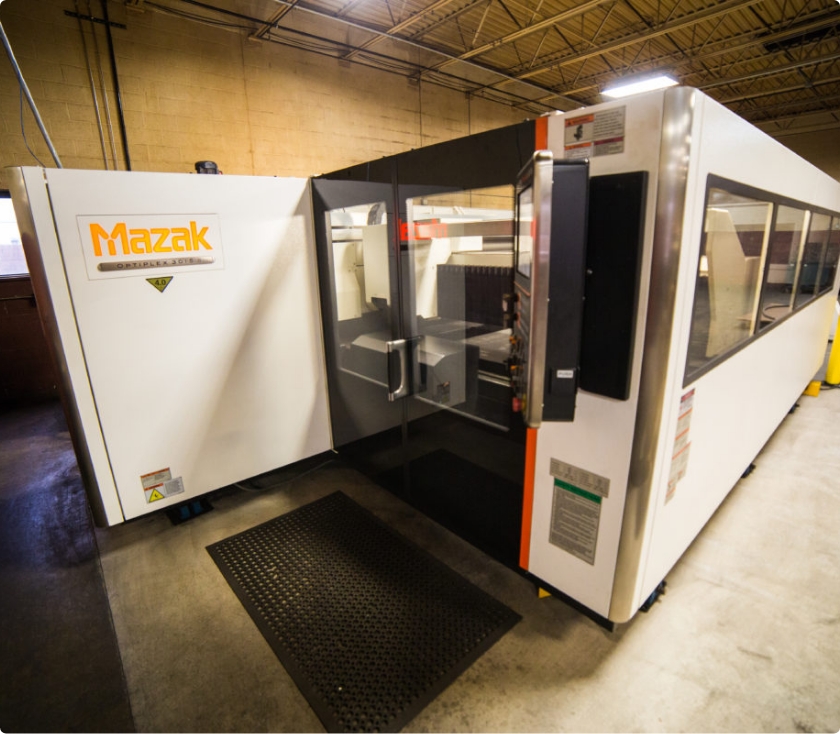

4000 Watt Mazak Laser

- Automated Setup Precision: The 4000 watt Mazak laser at ReFab is equipped with advanced automated setup features, ensuring precision in material and thickness transitions. This automation allows for rapid adjustments, reducing downtime and optimizing production efficiency.

- Swift Material and Thickness Changes: Capable of changing between materials and thicknesses in less than 1 minute. This swift adaptability facilitates on-the-fly adjustments.

- Just-in-Time Production Advantage: This approach eliminates the need for batch processing, allowing us to focus on individual parts with diverse setups. This not only enhances efficiency but also ensures optimal resource utilization.

- Versatility Across Materials: Handles 1" mild steel, 3/8" aluminum, and stainless steel with equal precision. This versatility makes it a go-to solution for projects spanning various industries, providing adaptability and consistency across diverse material requirements.

- Optimized Workflow Flexibility: Whether it's a prototype, a small production run, or a large-scale project, our laser's adaptability ensures that we meet your specific needs with maximum efficiency.

- Cutting-Edge Precision in Every Project: The 4000 watt Mazak laser is not just a tool; it's a precision instrument. The advanced technology ensures that each cut is executed with meticulous accuracy, meeting and often exceeding the strictest industry standards.

Mazak Super Turbo X48 laser cutting machine

Key Features of Our Mazak Super Turbo X48:

- 5' x 10' Travels: Our Mazak laser boasts a spacious 5' x 10' working area, providing ample space for handling a variety of metal sheets. This extended travel capability ensures versatility, allowing us to accommodate diverse project sizes with ease.

- Pallet Changer for Seamless Workflow: Efficiency is at the core of our operations, and the pallet changer in our Mazak laser contributes significantly to streamlined workflow. With two pallet tables, we achieve higher throughput, enabling continuous production without unnecessary downtime.

- Cutting-Edge Precision in Stainless Steel and Aluminum: Elevate your projects with the ability to cut 3/8" stainless steel and aluminum with utmost precision. Our Mazak laser is engineered to handle these materials with finesse, ensuring clean, accurate cuts that meet the highest industry standards.

- Heavy-Duty Mild Steel Cutting: When it comes to mild steel, our Mazak Super Turbo X48 rises to the challenge, offering 3/4" cutting capabilities. This heavy-duty performance is ideal for projects requiring robust and durable mild steel components.

Uncompormised Craftsmanship