Add Machined Features and Components to your parts

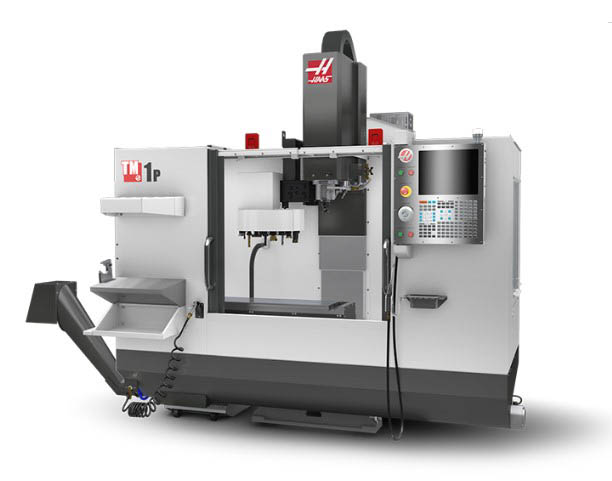

Key Advantages of ReFab's CNC Machining Capabilities:

- Precision Machined Features: Our CNC machining capabilities allow us to achieve intricate details, tight tolerances, and geometric precision, ensuring the utmost accuracy in every component.

- Tailored Components for Unique Requirements: Every project is unique, and our CNC machining expertise enables us to tailor components to your specific requirements. Whether it's creating complex geometries, fine-tuning surfaces, or integrating specialized features, ReFab can customize components with precision.

- Seamless Integration with Fabricated Parts: The synergy between our metal fabrication and CNC machining processes ensures seamless integration of machined features and components. This holistic approach results in parts that meet structural requirements and exhibit refined machining details.

- Materials Expertise: ReFab's expertise ensures that machined features are executed with consistency and quality.

- Efficiency in Production: By consolidating metal fabrication and CNC machining under one roof, ReFab streamlines the production process. This integrated approach not only ensures efficiency but also facilitates clear communication and collaboration between fabrication and machining teams.

Uncompormised Craftsmanship